Mounting samples is an important step in determining the overall quality of a sample preparation. Choosing the right mounting process and consumables is dependent on the type of sample and the objective of analysis. Ideal mounting processes would consider environmental safety, productivity of the mounting process and ease of polishing the mounted samples.

Advantages of mounting:

- Specimen identification

- Easier handling and storage

- Edge retention

- Safety from sharp corners

- Extended life of polishing pads

- Filling holes, cracks or open-porosity in samples

The Mounting Process

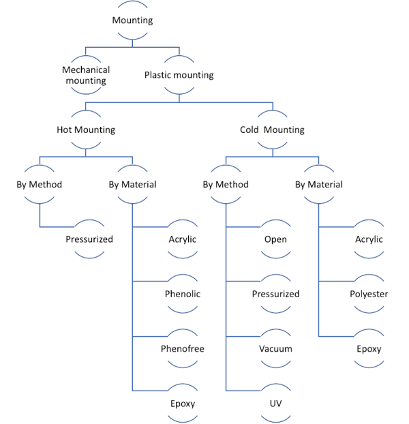

Figure 1: The Mounting Process

Today, the most popular type of mounting used is resin-based mounting. However, some laboratories use mechanical mounting systems to increase productivity of sample preparation processes.

Resin-based mounting systems:

Hot mounting: Heats resin powders to over 170 °C and compacts the resin using pressure inside a mounting chamber. Check out our hot mounting resins here.

Cold mounting: Uses polymerisation to harden a viscous mix of components (usually a resin and a hardener) in a mounting mould. Check out our cold mounting resins here.

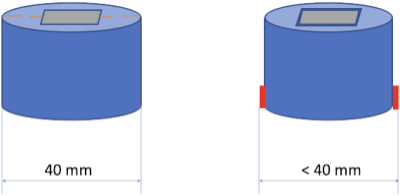

When choosing a mounting process, a critical condition is the size of the mount chosen. The diameter of the mount should be close to that of the sample; having a mount that is too large or too small will impact the polishing quality. Ideally, there will be a minimum of 3 mm from the edge of the sample to the edge of the mount, and maximum of <50% of the diameter of the sample. While most mounts are cylindrical, rectangular mounts are available for specific applications. Take a look at the mounts we offer here.

Choosing a mounting method

Temperature and pressure

For samples that can withstand temperatures over 170 °C and loads over 1000 daN, hot mounting can be used without altering the microstructure.

For samples which will be sensitive to these temperatures, cold mounting is preferred.

Mounting of intricate shapes

When cold mounting, the resin should be chosen based on the characteristics of the sample. If the sample is particularly porous, some resins cannot enter the intricate gaps in the sample. Depending on how porous the sample may be, cold mounting can be carried out under pressure or under vacuum.

When mounting under pressure, use a compressed air pump such as the MM808. This pushes the resin into the sample from various directions, avoiding bubbles of air in the resin. For open porosities, a vacuum such as the MM818 can be used.

Time constraints

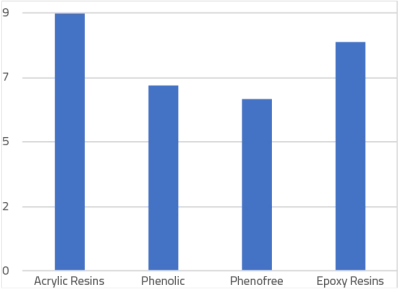

Hot mounting is the most time-efficient method of mounting. Shown below is the duration of isothermal holding time at peak temperature combined with cooling time for making 30 mm mounts in a mounting press.

Figure 2: Mounting time (Heating + Cooling cycle) for frequently used Hot Mounting Resins in a 30 mm chamber.

Mounting time is not influenced significantly by the type of resin chosen in hot mounting, compared to cold mounting where duration changes significantly based on the type of resin. Shown below are mounting times for cold mounting resins by type.

| Resin type | Curing time |

| Acrylic Resins – Lam Plan 605, 609 | 9-15 min |

| UV-cured acrylic resins – Lam Plan 601.2 | 10-30 min |

| Polyester Resins – Lam Plan 607 | 15-20 min |

| Epoxy Fast Curing – Lam Plan 613F | 2-3 hours |

| Epoxy Slow Curing – Lam Plan 613LT | 24 hours |

Choosing a mounting resin

Resins can be chosen based on two criteria, dictated on application and material:

- Significance of resin shrinkage

- Hardness and abrasion resistance of the resin

Shrinkage and edge retention

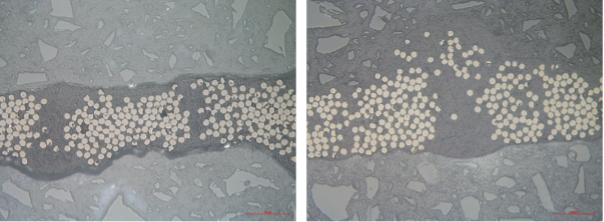

Edge retention is a key reason for mounting samples. Resins shrink on polymerisation, and this is the same of mounting resins. Shrinkage introduces a gap between resin and the sample, which can be detrimental for microstructural analysis.

The gap can affect polishing quality of the sample, as abrasives can get stuck with the gap which could be released at a later stage of polishing. This leads to significant scratching after fine polishing. When analysing delicate coatings, these gaps can result in damage while polishing.

Since etchants can penetrate the gaps and escape during analysis, etch-homogeneity across the surface is largely reduced by these gaps.

Figure 3: Shrinkage in a resin while hardening creating a gap between the specimen and the resin.

While the expected diameter of the sample is 40 mm, the resulting diameter is usually less 40 mm.

Figure 4: Good and bad edge retention in a fibre-reinforced composite.

The microstructure on the left shows a huge gap at the boundary of the composite resulting in a bad edge retention after polishing. In contrast, the image on the right mounted using the right process shows no such gap resulting in a good edge.

Importance of hardness

Resins designed for metallographic mounting purposes have a hardness of around 80 Shore D. However, there are resins available which are harder and more abrasion-resistant than this, and their hardness relative to the hardness of the sample can affect the performance of following polishing steps.

For example, when polishing a sample that is too hard and a resin is too soft, grinding the sample results in differential material removal across the sample. This creates poor flatness of the sample or deep scratches around the edge of a sample.

Abrasion resistance of resins for metallographic applications is in the following order:

- Epoxy resins (hardest)

- Polyester resins

- Phenolic resins

- Acrylic resins (softest)

Special applications

Some applications require special characteristics from mounting resins:

Recovery of mounted specimens

For example, industries working with precious metals. In this case, the choice of resin is limited to soluble acrylic resins such as the Resin 605, which can be dissolved in acetone.

Mounting for Electron Microscopy

When mounting for EM, it is critical for the mount to be conductive, as non-conductive resin can result in charging of electrons on the specimen surface, resulting in poor image quality. In this case, a phenolic or acrylic mounting resin with copper or graphite fillers are best.

To discuss your application and find out what resin is best for you, please contact our sales team: [email protected]