The experimental volcanology and geothermal research group at the University of Liverpool, supervised by Prof. Yan Lavallée, focus on investigating the mechanical and textural properties of magma and rocks at high temperature.

Two of the PhD students in the research group, Josh Weaver and Jenny Schauroth, use a WELL Diamond Wire Saw in their work to section delicate volcanic material. This is what Josh had to say, along with the great image they provided:

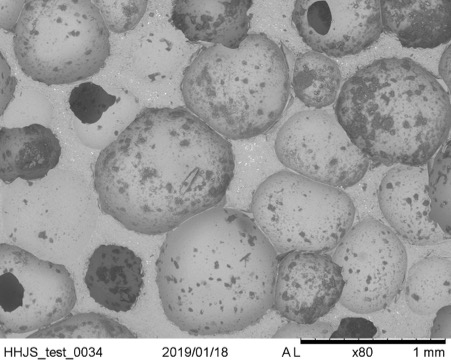

“The image shows a sample of obsidian (volcanic glass) that has been heated to a liquid state in a furnace, allowing the dissolved gases in the magma to form bubbles.

The standard approach to producing these SEM images involved setting the sample in epoxy resin and manually polishing it for several hours. The wire saw reduces this preparation time drastically as the sample face is polished by the cutting, leaving no visible scratches. The sample in the image was placed in the SEM directly after cutting, with no other preparation required. The wire saw also has the ability to cut thin sections in the micrometer range and reduces precious sample waste.”